CERAMIC SUBSTRATE

Introduction

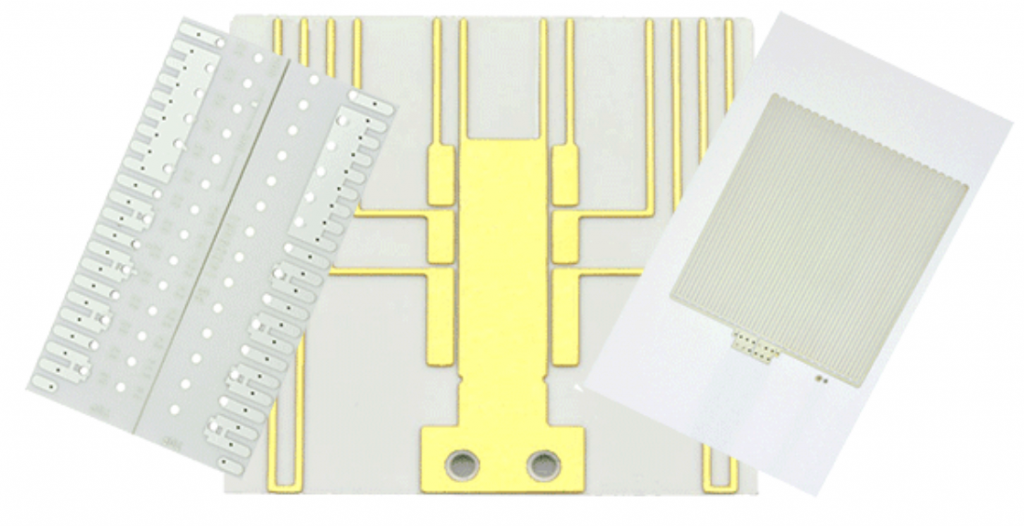

Currently, there are four main types of substrate materials commonly used in electronic packaging: 1) Polymer Substrate; 2)Metal Substrate; 3)Composite Substrate; 4)Ceramic Substrate. Ceramic circuit boards are made of Advanced Ceramic Materials and it is widely used in electronic packaging substrate for its advantages such as high strength, good insulation, good thermal conductivity and heat resistance, small thermal expansion coefficient and good chemical stability.

Ceramic Substrate Advantage

Unlike traditional FR-4, ceramic materials have good high-frequency performance and electrical performance, have high thermal conductivity, chemical stability, excellent thermal stability, and other properties that organic substrates do not have. The Main advantages :

- Higher thermal conductivity and heat resistance.

- Smaller thermal expansion coefficient.

- Stronger and lower resistance metal film alumina ceramic circuit board.

- Good electronics insulation.

- Low high-frequency loss.

- Excellent thermal Stability.

According to Material

Alumina Substrate

Alumina Substrate (Al2O3) is the most commonly used substrate material in the electronics industry, because of its mechanical, thermal, and electrical properties compared to most other oxide ceramics, it has high strength and chemical stability, and is rich in raw materials. It is suitable for various technical manufacturing and different shapes.

Features:

- Good surface with high smoothness/flatness and less porosity.

- High resistance to heat shock.

- Excellent resistance against oil and chemical.

- Low warpage and camber.

- Stable in very high temperature and corrosive chemical.

- Very stable breaking strength and shape/dimension variance.

Application: High dissipated ceramic circuit board for LED, Power module for the automotive, RF modules.

AlN Substrate

AlN Substrate, there are two very important properties of AlN : one is high thermal conductivity, and the other is the expansion coefficient matching Si. The disadvantage is that even if there is a very thin oxide layer on the surface, it will affect the thermal conductivity. Only by strictly controlling the materials and processes can we produce an AlN substrate with good consistency. At present, compared to the Al2O3, the price of AlN is relatively high. In the future with EV and 5G communication market grow up , it will play the most important role in it!

Features:

- High thermal conductivity, 7 to 8 times as much as alumina.

- Thermal expansion is close to silicon wafer.

- Excellent resistance against oil and chemical.

- Higher electric insulation, and Smaller dielectric constant.

- High density and high mechanical strength.

- Superior corrosion resistance against molten metal.

- Very high purity, no toxicity.

Application: High Power Modulus, IGBT, MOSFET, High power LED package.