Features

Calcined Alumina is produced through the calcination (“heating”) of alumina to various temperatures. By controlling the calcination temperatures and time, the properties of the alumina can be controlled.

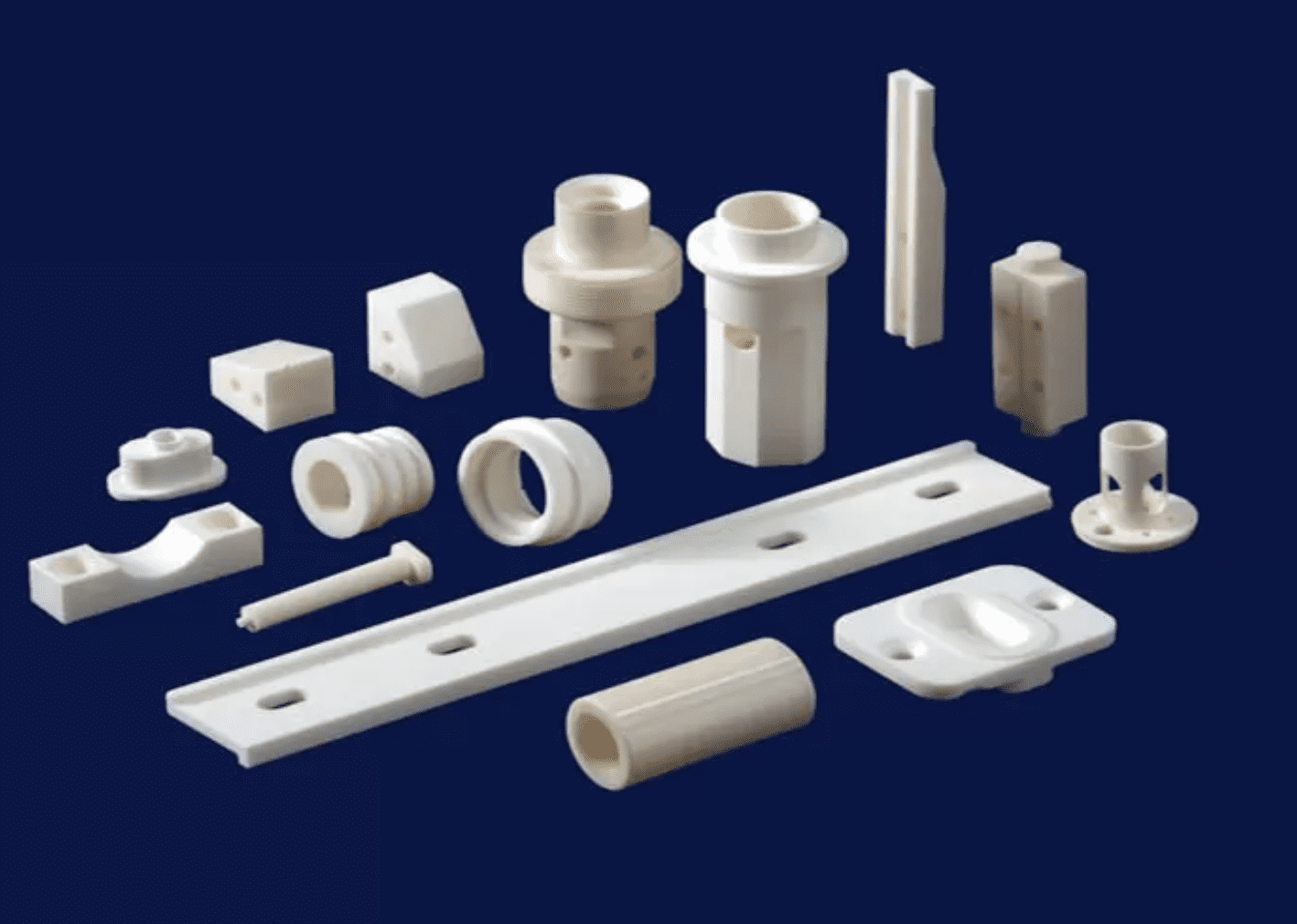

These alumina grades are white crystalline powders that are predominantly alpha Alumina of high chemical purity and consistent physical properties. The specific properties include extreme hardness, refractoriness, high mechanical strength and resistance to wear abrasion, chemical attack, and corrosion.

Soda content is a major factor in determining the final use (low soda materials are used for electronic applications, medium soda for electrical insulation and porcelains, high soda for glass, glazes and fiberglass).

Applications

Calcined alumina is used as structural ceramics, polishing compounds for plastic, metal, and glass, fillers for rubber and plastics, refractories, paint & coatings and thermal spray powder.